6 what are the basic principles behind rockwell hardness tests|background of rockwell hardness testing : convenience store The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation. 1 dia atrás · Highlights include a Mega Accumulator Tip at odds of 43/1, a Best Boost of the Day Tip at 6/4, and a Luton vs Man Utd Bet Builder Tip at 33/1, among other enticing selections. Our Bet of the Day has been on fire, winning 5 of the last 7, and is pegged at odds of 5/6 today.

{plog:ftitle_list}

Sinopse. Documentary about the U.S. Air Force's P-47 Thunderbolt bomber's role in the Italian Campaign. Cast. James Stewart. Himself. Robert Lowery. Narrator. Lloyd Bridges. .

rockwell hardness testing method

What is the Principle of the Rockwell Method? You can think of the Rockwell Hardness method as an impact-dependent hardness measuring method. The reason is that it requires an indenter with a known diameter and a specified load to impact the surface of the .Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth . The Rockwell hardness test is the industry standard measuring system used to determine how resistant a material is to another object. Hardness is defined as a material’s resistance to permanent indentation.

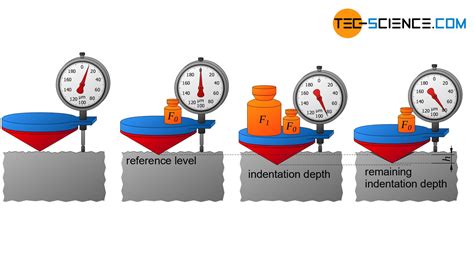

First, the indenter is forced into the test material under a preliminary minor load. This depth is recorded. Then, with the minor load still applied, an additional load is introduced. This is known as the major load, and it increases the depth of .

rockwell hardness tester least count

rockwell hardness test theory

The Rockwell method is a static hardness testing method, which can be further characterised as follows: It is one of the standardised procedures (ISO 6508, ASTM E18). The process is used to test hardness in the macro range (test . In the macro range (traditional hardness range), tests are conducted using large test loads ≥ 5 kgf, which also correspondingly produce large hardness indentations on the test pieces. Hardness test methods used .The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics .

TEST TYPES. Rockwell Hardness Testing. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the permanent depth of the .

Classification, process, differentiation and practical recommendations. Here you will find useful information on the basics of hardness testing, the most common standardized test methods Rockwell, Brinell, Vickers and Knoop as well as .ACKNOWLEDGMENTS Theauthorwouldliketothankthefollowingpersonsforsharingtheir experienceandprovidinginformationforthisGuide.Theirinputandreview .Two common hardness tests are used in the industry: the Rockwell scale and the Vickers scale. Both test the surface of a material, but they are used for different purposes. The Rockwell hardness test measures the hardness of all metals except in conditions where the structure of the test sample would cause too much variations, or the indentations formed would be too .

This article discusses methods and the principles behind hardness testing. Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and .Explore the different methods of measuring material hardness, including scratch, indentation, and dynamic hardness tests. Understand the principles behind the Brinell, Meyer, Vickers, Rockwell, and Microhardness tests, and their applications in engineering and metallurgy. Learn about hardness measurement at elevated temperatures.

Rubber Brittleness Tester store

High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the resistance .

Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests.The Rockwell hardness test is an empirical indentation hardness test that can provide useful information about metallic materials. This information may correlate to tensile strength, wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control and selection of materials. .The Rockwell hardness test and Vickers hardness test are two commonly and widely used techniques among the many hardness testing methods. They can test different types of materials. Rockwell and Vickers hardness tests adopt other principles and testing methods, respectively. They have their own unique advantages and applicable scenarios. Vickers Hardness Test. . the necessary calculations are independent of the indenter size and it can be used for all materials regardless of hardness. The basic principle of Vickers hardness tester, as with all common hardness measures, is to observe the ability of a material to resist plastic deformation from a standard source. The Vickers .

Advantages of Rockwell Hardness Test. Typically, the Rockwell test is easy to execute and more precise than other kinds of hardness evaluations. The Rockwell test technique is used on all metals, except when the test would introduce too many surface variations; when indentations would be too large; or where the sample otherwise prohibits its use.The Rockwell hardness test is less affected by surface rough-ness compared to other methods such as the Vickers or Brinell tests. It can provide reliable hardness measurements even on surfaces with moderate roughness, making it a practical choice for a wide range of materials and surface conditions.

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the . Rockwell Hardness Standard Test. The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter into the surface of a material. Hardness is evaluated by measuring the difference in depth of .

(4) Selection of F and D (principle of geometric similarity of indentation) When measuring Brinell hardness with indenters of different diameters and loads of different sizes, the principle of geometric similarity .

Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that .

In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test .Rockwell hardness test measures the permanent depth of indentation on the material by applying a fixed load using an indenter. The smaller the indentation value, the harder is the material. The Rockwell hardness test follows the principle of the differential-depth method. Here, the indenter makes a residual depth called the indent and it is .

The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels. Types of Hardness Tests. There are several types of hardness tests, each designed to measure different material properties. The most common types of hardness tests are: Rockwell Hardness Test: This test measures the depth of penetration of an indenter into the material. The Rockwell hardness test is the most commonly used hardness test in the . The Leeb Hardness Test, also known as the rebound hardness test, measures hardness by analyzing the rebound of an indenter, rather than the size of an indentation. It is portable and ideal for on-site testing of large and heavy components, offering a non-destructive method that causes minimal damage to finished parts and coatings. The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. . The rationale behind the Rockwell method is that the durability of a material is better gauged on its ability to maintain structural integrity from damages that are not .

1.3. Rockwell Hardness Test: The Rockwell hardness test also uses a machine to apply a specific load and then measure the depth of the resulting impression. The indenter may either be a steel ball of some specified diameter or a spherical diamond-tipped cone of 120° angle and 0.2 mm tip radius, called brale.Best Practices for Rockwell Hardness Testing Hardness Testing Basics Hardness, as applied to most materials, and in particular metals, is a valuable, revealing, and commonly employed mechanical test that has been in use in various forms for more than 250 years. As a material property, its value and importance cannot be understated; the information

The Rockwell hardness test is one of several common indentation hardness tests used today, other examples being the Brinell hardness test and Vickers hardness test. Most indentation hardness tests are a measure of the deformation that occurs when the material under test is penetrated with a specific type of indenter . In the case of the .Hardness tests help to decide the resistance of a material to deformations. Brinell and Rockwell hardness tests are the most common hardness tests used. Key Takeaways. Brinell hardness testing uses a spherical indenter and measures the size of the indentation, which is suitable for testing large samples and rough surfaces.

VIM, International vocabulary of metrology ? Basic and general concepts and associated terms, VIM, 3rd . related to conformity assessment, as well as information about ISO's adherence to the World Trade Organization (WTO) principles in the Technical Barriers to Trade . Hardmetals — Rockwell hardness test (scale A) — Part 1: .

rockwell hardness test calculation

WEB♥Welcome to the channel♥ My name is Jessica and I am Hollō. Im an illustrator who loves the Sims 4. Most of my videos will be Sims 4, but there might be other games as well. .

6 what are the basic principles behind rockwell hardness tests|background of rockwell hardness testing